The basic features that have made Dillon vibrating screens unique are:

Our engineering application department has years of experience in sizing Dillon screens to suit the customer’s requirements.

When We Quote A Job, You Can Be Sure Our Design Will Meet Or Surpass Your Performance Expectations!

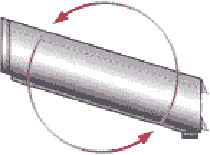

Eccentric shaft produces a true circle vibration that gives a full floating motion. Material is rapidly stratified. Undersize has maximum time to work down through the bed of material and pass through the screen cloth.

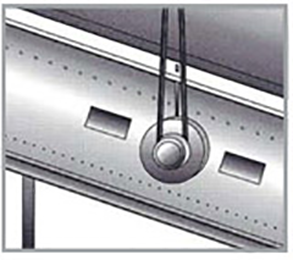

Eccentric shaft operates with only two anti-friction roller bearings, so horsepower costs are reduced up to 50%. Construction, maintenance and operating costs are lower, and floor space requirements are less than for comparable 4-bearing screens.

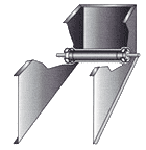

Unique design and construction makes maintenance and parts replacement simple. When the long-wearing screen cloth must be changed, access ports in the sides of the screen body simplify the job. Vibrating mechanism can be removed from either side of the screen body. Mechanism is lubricated through grease pipes outside the screen body. The economical 2-bearing screen means not only lower operating cost, but also lower initial cost for screen and motor.

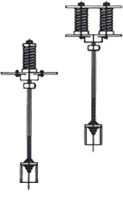

The entire weight of the screen and feed load is suspended from four spring-mounted rods. The springs absorb any any shock load, so it is not transmitted to the bearings, unlike screens where the bearings carry the load. Vibration is confined to the screen body, reducing transmission to the supporting framework or to the building.